The production process of the 5t per hour organic fertilizer production line is roughly the same as that of the ordinary organic fertilizer production line, but the details are different. These details affect the effect of the entire production line and customer satisfaction. Next, I will introduce it from multiple perspectives such as the site, equipment, and cost of the production line.

How to make organic fertilizer at 5t/h?

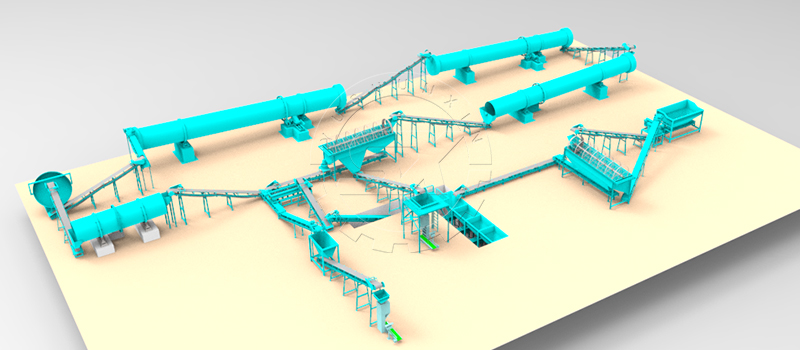

5t organic fertilizer production line set up plan

Some customers have space to buy production lines, and some customers do not have space. Our company will help customers solve site problems according to different situations.

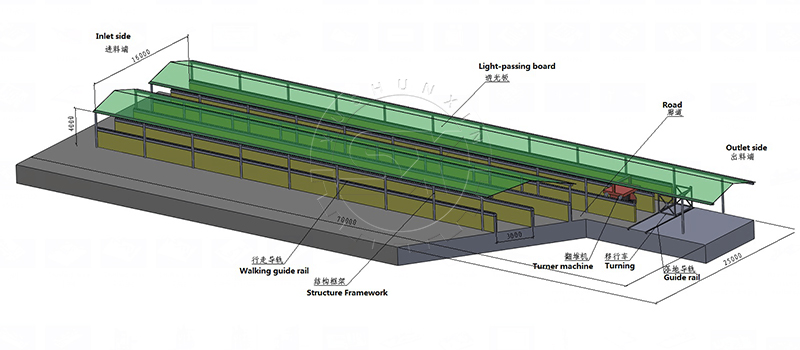

Matters needing attention to 5t/h organic production line about fermentation

The fermentation process in the early stage of the organic fertilizer production line is very important. This process determines the fertilizer efficiency of the fertilizer in the later stage, so you need to pay attention to some details.

Budget of 5t organic fertilizer plant

The overall budget for the production line is $150000-200000. But there are many other costs that customers are concerned about.

Cost

Such as labor costs. If you have a groove type composting machine for turning over, which requires one person to drive. Forklift feeding may require one person to drive. Packing requires 2-3 people, because both sewing and palletizing require hands.Therefore,customers need to concern about labor costs.There is also the cost of renting a house, electricity consumption and heat source consumption based on the size of the plant.

Income

In addition, customers also concern the income of the fertilizer produced . Granular fertilizer sells 150-200 US dollars per ton, and powdered fertilizer sells 100-150 US dollars per ton.

The budget starts from a comprehensive perspective, so that customers can better maximize the role of the production line.

Heat source consumption for making 5t/h organic fertilizer production

Customers generally have two options for the drying process: self-built and purchased equipment.

Wearing parts’ replacement for 5t/h organic fertilizer production process

You need to replace the wearing parts in the 5t per hour organic fertilizer production line in time. If you are not replace, it will not only reduce your production efficiency, but also damage the equipment and reduce your service life over time.

These wearing parts can maintain a service life of 6-8 months, and you need to replace every six months to effectively ensure your efficiency of fertilizer production.

How can I adjust granular sizes if I want to make 5t/h organic fertilizer using your plant?

Particle size is important to the expression of the final product. In order to better adjust the particle size, you can equip a fertilizer screening machine after granulation. You can customize the screen mesh of the fertilizer sieving machine according to the particle size you want, and screen the particles that meet your requirements after granulation. Others can be re-granulated and re-sieved so that you end up with your desired particle size.