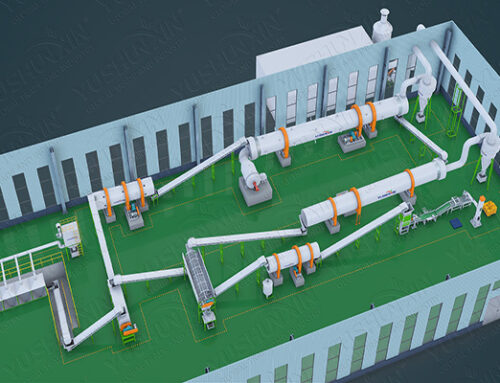

Are you finding a solution for making BB fertilizer from your factory? Do you plan to start a small scale BB fertilizer preparation out of a few material? SX 10 t/h fertilizer blending system is an ideal choice. It can help you process types of materials into granular fertilizer quickly and easily. So it is popular with BB fertilizer manufacturers. Then what is the configuration of this 10 t/h bulk blending fertilizer making system? The solution is as follows:

How Does 10TPH Fertilizer Blending System to Produce Bulk Blending Fertilizer?

In general, a 10 t/h bulk blending fertilizer manufacturing system can be divided into three parts. Feeding, mixing and packaging. For every step, as a professional fertilizer equipment company, SX can provide you with the most suitable equipment.

Feeding Chemical Pellet Materials in Required Proportions

For bulk blending fertilizer production, proportions of feeding materials is essential. It is the secret of making fertilizer which is popular with local farmers. For 10 t/h BB fertilizer making, we recommend you buy static batching equipment. It adopts an electronic control system on material hoppers, so it is able to feed chemical materials such as urea, DAP, MOP, etc strictly according to the required volumes. Therefore, you can produce quality chemical blending fertilizer you need.

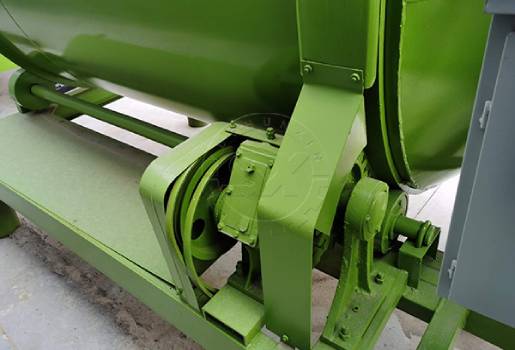

Mixing Various Materials Evenly

Next, the most important step – mixing various materials evenly. For small scale 5-10 t/h BB fertilizer making, most fertilizer manufacturers choose our BB fertilizer mixer with special internal screw mechanism and unique three-dimensional structure. It mainly utilizes the forward and reverse rotation to finish material blending and discharging. When the BB fertilizer mixer rotates clockwisely, the internal fertilizer materials are continuously picked up and then roll and drop because of gravity. During this process, various chemical pellets will be mixed evenly. Then making the machine rotate counterclockwisely discharge the bulk blending fertilizer products.

Packaging Finished BB Fertilizer

Finally, packaging finished BB fertilizer into bags. You can choose to pack your fertilizer into 10 kg/bag, 25 kg/bag, 50kg/bag, etc. This is beneficial for selling your fertilizer to customers with different volume requirements in a targeted way. Here, we can provide you with automatic packaging equipment.

What is the Cost of 10TPH Fertilizer Blending System?

Why So Many Customers Want to Invest the Fertilizer Blending System?

If a product wants to attract customers to buy it, it should have its own highlights. Of course, the BB fertilizer manufacturing line is the same. It has various advantages to improving its competitiveness in the market.