Are you searching for effective solutions to handle organic waste disposal? Are you curious about the different business plans available for organic fertilizer production? Do you need reliable machines for your upcoming organic fertilizer project? Look no further than SX! As a leading fertilizer equipment factory, SX boasts cutting-edge technology and years of experience in manufacturing top-quality organic fertilizer machines. Alongside our premium equipment, we also offer a wide range of customizable business plans tailored to your specific needs. Contact us now and let us assist you in smoothly launching your organic fertilizer production project.

- 1

Capacity: 1-20 t/h

- 2

Area: 800-10000㎡

- 3

Equipment Material: Carbon steel Q235 / Alloy

- 4

Voltage:220v/380v/415v/440v/480v(50Hz/60Hz)

- 5

Application: Dispose of animal manure waste, straw, rice hull, biogas residues, sludge, etc.

Fertilizer production projects for making powdery and granular organic fertilizer

In general, most organic fertilizer manufacturers prefer to prepare organic fertilizer into two forms. Powdery and granular. So in order to meet the different requirements of our customers, we especially design powdery organic fertilizer production project and granular organic fertilizer production line separately.

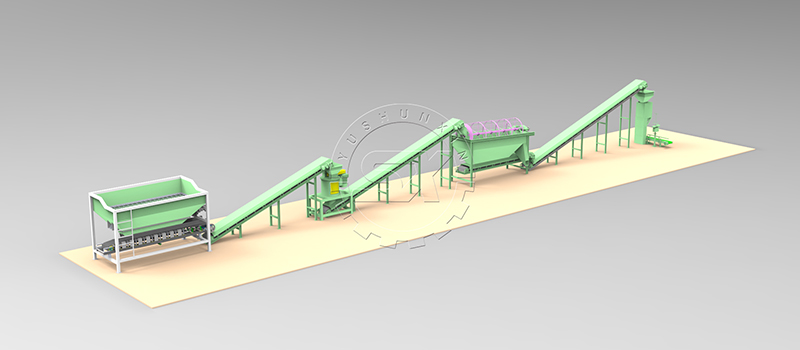

Powdery organic fertilizer making project design

Powdery organic fertilizer manufacturing line is a straightforward process that transforms organic waste into fertilizer. By using only a few fertilizer machines, you can easily accomplish the task of organic fertilizer making. The necessary machines include a dehydrator, composting machine, loader type feeder, organic waste crusher, powder screener, powder packaging machine, and belt conveyor. This efficient line of production allows you to effectively convert organic waste into high-quality fertilizer.

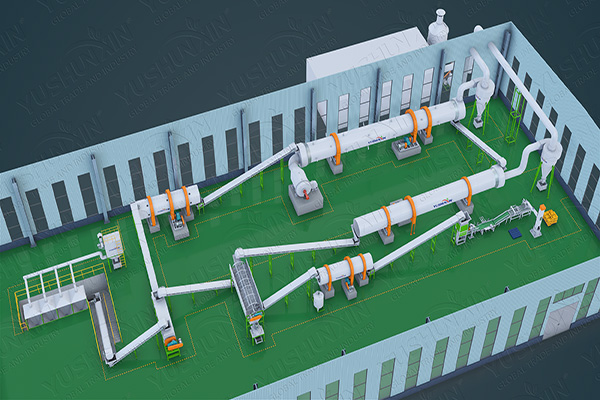

Granular organic fertilizer production system technology

When you want to further process organic fertilizer, you have the option of converting powdered compost organic fertilizer into granules. This process, however, requires more advanced machinery. In order to set up a complete granular organic fertilizer production line, you will need a variety of equipment, such as dehydrator compost machine, batching machine, crusher, mixer, granulator, screening equipment, dryer&cooler, coating machine, packaging machine, belt conveyor, and dust collector. By selecting these machines, you can customize your own organic fertilizer production plan to suit your specific requirements.

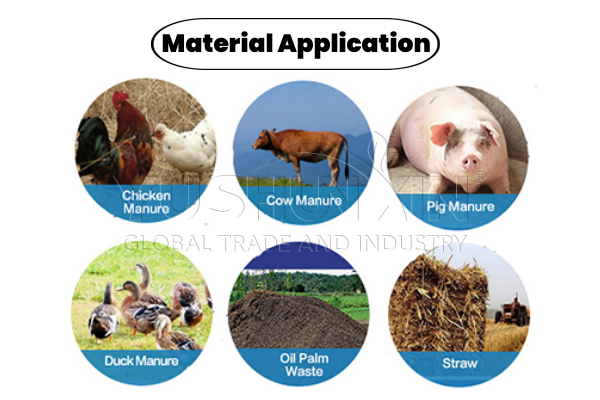

What materials can make organic fertilizer?

Materials preparation is the basis of making high quality organic fertilizer. In general, there are various materials can be used to produce organic fertilizer. Including animal manure, agricultural waste, industrial residue, biogas residue etc. Knowing more about them can make it easier to prepare organic fertilizer you need.

Which composting method is suitable for fermenting organic fertilizer material?

Composting is crucial for the production of organic fertilizer, and it is necessary to find ways to compost organic waste quickly. To achieve this, we recommend utilizing a professional compost machine. There are generally three methods to prepare compost: groove composting, windrow composting, and in-vessel composting. You can choose the method that suits your needs best. Whichever method you opt for, we can supply you with high-quality composting equipment specifically designed for fertilizer production.

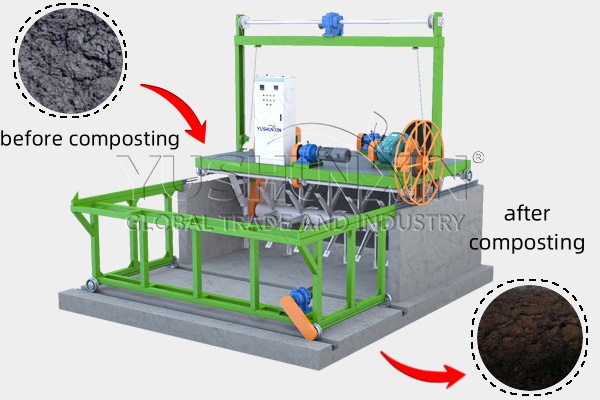

Groove composting for both large and small scale compost production

If you are planning to produce organic fertilizer on a large scale, we highly recommend choosing composting materials in the trench. The compost trench you can build has a wide range of 30m and a depth of 3m, offering ample space for your production needs. By increasing the number of trenches, you can easily expand your organic fertilizer production scale. To facilitate the process, our compost turning equipment can be combined with a transfer vehicle for multiple-groove fermentation. For large-scale composting, the wheel type compost turner is an optimal option. Alternatively, if you are engaged in small-scale composting in grooves, the groove type composter and chain plate composter would be ideal choices. Using these efficient tools will ensure a smooth and productive composting process.

Windrow compost – no extra building

If you prefer to create compost fertilizer directly on the ground, the windrow composting method may be more suitable for you. This approach involves placing the raw materials in long windrows and using a windrow compost turner to turn them. After approximately 20 days, you will obtain high-quality compost. The windrow composting method offers many advantages, including low cost, high flexibility, and easy operation. If you are interested in utilizing this composting technique, you have the option to choose between the crawler type compost turner and the moving type compost turner. Both options are effective for composting various materials.

In-vessel composting for faster fermentation

If you’re looking to accelerate the fermentation of materials, you may want to consider using in-vessel composting equipment. This equipment utilizes a closed fermentation method, allowing for the completion of the harmless treatment process in just 10 hours. What’s more, it comes equipped with a professional gas waste recycling system, meeting your requirements for environmentally-friendly composting. To cater to the diverse needs of our customers, we have designed two types of fertilizer fermentation tanks for you to choose from: the vertical fertilizer compost pot and the horizontal fermentation tank. These options provide you with flexibility in selecting the best fit for your specific needs.

Top 5 organic fertilizer granulators for your choice

When selecting organic fertilizer granule production machine, you need to consider from many aspects, especially the capacity. For small, medium and large scale organic fertilizer granulation, you need to choose different types of organic fertilizer pellet making machines.

What is the approximate budget for organic fertilizer manufacturing business?

Operating your own organic fertilizer manufacturing plant, there are is important factors which you should consider. Firstly, you should rent a factory for setting the fertilizer machines. And then it is necessary for you to prepare suitable raw materials for manufacturing. Besides, it is important for you to selecting a set of high quality organic fertilizer processing machines.

Why should you choose automatic equipment,not manual in your organic production project?

The equipment produced by our company has a high degree of automation and a variety of ingredients. I will introduce it in detail below.

Our company’s equipment will definitely satisfy you. If you want to know more, welcome to consult.