What material can you process for water soluble fertilizer production?

If you want to produce different water soluble fertilizer, material selection is necessary. Because it can decide you making the kind of water soluble fertilizer.

When you prepare to make organic water soluble fertilizer, you can use animal manure, such as cow dung, chicken manure, piggy waste,etc and agricultural litters, such as straw, sawdust, crop stalks, etc as materials. Then through using solid liquid separator, you can get the organic waste liquid&solid material. After that, during the production of water soluble fertilizer, liquid material can undergo certain treatment to produce liquid water soluble fertilizer. And solid material can also be used in organic solid water soluble fertilizer manufacturing.

For producing NPK water soluble fertilizers, you can collect rich nitrogen, phosphorus and potassium as ingredients for plant growth. While selecting nitrogenous raw materials, you can use urea, ammonium nitrate and ammonium sulfate. And as for phosphorus-containing raw materials, you can choose monoammonium phosphate, diammonium phosphate, etc. as raw materials to make NPK water soluble fertilizer. Finally the raw materials rich in potassium are potassium chloride and potassium nitrate.

What types of water soluble fertilizers can you make?

When you want to make water soluble fertilizer, there are two types of fertilizer for your choice. Liquid and solid. You can choose them according to your requirements.

Liquid fertilizer

Compared with traditional fertilizer, liquid water soluble fertilizer has inherent advantages. Because it dissolves quickly and is easier for plants to absorb nutrients than solid fertilizer. Moreover, you can flexibly adjust the production formula according to production needs. For this, it is an ideal choice for irrigation systems.

Solid fertilizer

If you prepare to produce solid water soluble fertilizer, it is convenient for you to store and transport them. And this type of water soluble fertilizer’s market is more popular in fertilizer production. So, making solid water soluble fertilizer is also a good choice.

How to manufacture liquid water soluble fertilizer?

If you want to make liquid water soluble fertilizer, the process is very simple. The details are as follows:

Raw material selection

When you prepare to produce liquid water soluble fertilizer, material selection is necessary. You can choose biogas liquid and waste water from livestock and poultry as materials to make organic liquid water soluble fertilizer. And for straight fertilizer and amino acid waste, you can produce compound liquid water soluble fertilizer.

Raw material process

For Organic Liquid Water Soluble Fertilizer Production

Fermentation-What method is used in liquid organic water soluble fertilizer reaction?

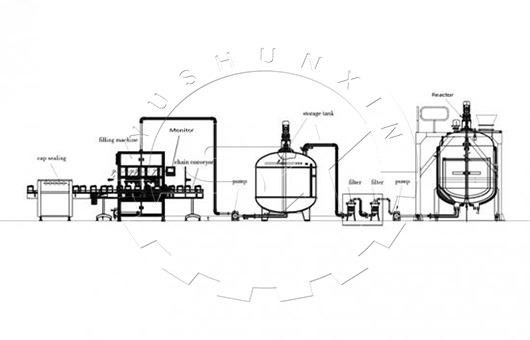

Liquid organic water soluble fertilizer has different fermentation methods from traditional organic fertilizer. You can adopt the sealed anaerobic fermentation method. So SX specially designed ananaerobic fermentation tank for the liquid fertilizer anaerobic fermentation. And the main body of such a fermentation tank is composed of an inner tank, a heat conducting layer and an insulation layer, which can effectively ensure the effect of anaerobic fermentation. Furthermore, there is an automatic exhaust system on the fermentation tank, which can exhaust the carbon dioxide produced by anaerobic fermentation.

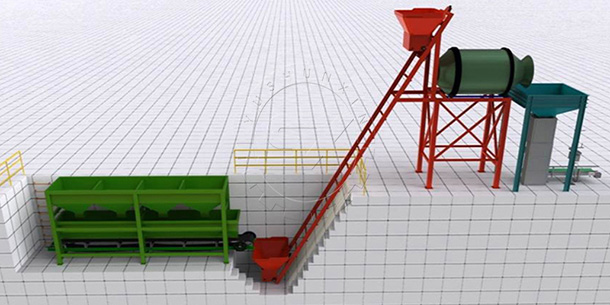

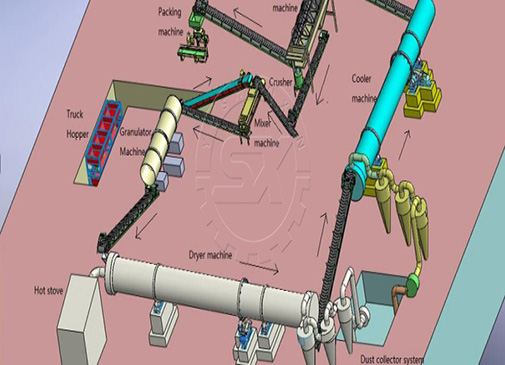

Business plans for making powder and granular water soluble fertilizer

In general, most fertilizer manufacturers prefer to prepare water soluble fertilizer into two forms. Powdery and granular. So in order to meet the different requirements of our customers, we especially design powdery water soluble fertilizer making line and granular water soluble fertilizer production line separately.

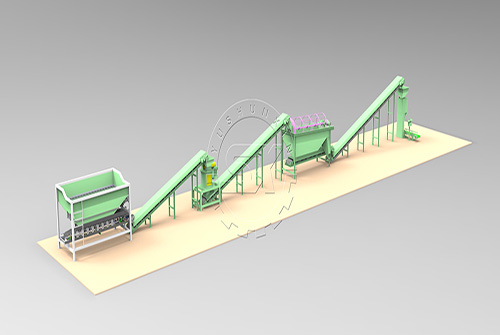

Can powder fertilizer make system produce water soluble fertilizer in a large scale?

Of course.The largest capacity of SX powder water soluble fertilizer making line can reach 20t/h or more. But it has characteristics of lower investment, less area occupation, high automation, etc. Therefore, it is a hot selling product for customers those who start water soluble fertilizer manufacturing initially. About a year, even less.