In NPK fertilizer making, phosphate fertilizer production is favoured by a large amount of fertilizer manufacturers. Because it contains rich phosphorus elements, which plays an important role in the germination and fruiting of plants. But how to make phosphate fertilizer pellets with low investment? On April 20th 2024, a customer from Russia inquired us for this question. After discussing, we gave him a reasonable solution. So the following are the specific information in this case:

- 1

Capacity: 10-15 t/h

- 2

Equipment Material: SUS304 stainless steel

- 3

Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- 4

Application: Phosphate rock to fertilizer pellets

How to start phosphate fertilizer pellets production with low investment?

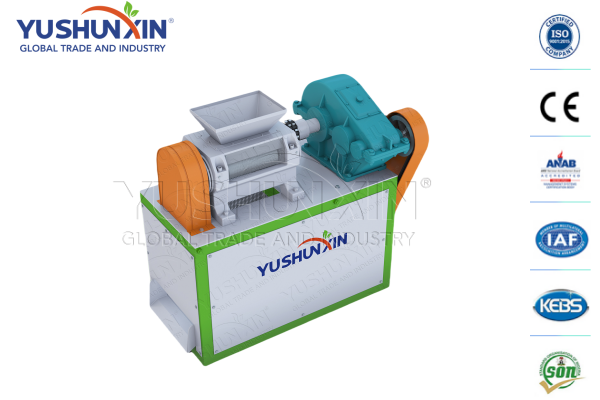

This customer told us that for a project in Russia, he needs a phosphate fertilizer production line for granulating with low investment and the expectant capacity is 10-15 t/h. Which pelletizer is suitable for this? Double roller granulator is an ideal choice for you.

Why do you choose this extrusion pelletizer? It can produce 1-2 t/h phosphate fertilizer pellets with low investment. But the capacity requirement of this customer from Russia is 10-15 t/h, can this granulator produce such a large capacity? Of course. You can buy 2-3 double roller extrusion pelletizers. After discussing with customer, he decided to buy two granulators for trial operation first and would continue to follow up if the production quality was high. Then because it adopts dry granulation method, you don’t need to dry and cool phosphate fertilizer pellets, which can reduce this cost. In general, this Russian client spend $86,699 to purchase two double roller granulators.

How to dispose of gas waste generated by phosphate fertilizer granules making?

For phosphate fertilizer pellets manufacturing plant setup, there is an item you need to pay attention to. It is gas waste treatment. In order to prevent environmental pollution according to Russian client’s local requirement, phosphate fertilizer making gas waste is essential. But how to make exhaust gas harmless? We recommend you buy our water curtain dust collector. Under the action of water, the gas waste will become hydrofluoric acid and hexafluorosilicic acid, which can meet the international discharging requirements.

The above are details about our communication with the customer about phosphate fertilizer pellets with low investment in Russia. In addition, we can also provide you with many other fertilizer production projects for fertilizer manufacturing. Such as NPK fertilizer production line, organic fertilizer granulation system, bulk blending fertilizer making line, etc.