We have a special plan for manure disposal on a scale of 100,000 chickens. You can use an organic fertilizer fermenter to ferment and decompose chicken manure. Chicken manure can also be turned into powdered fertilizer with 35000 US dollars or granular fertilizer with 110000 US dollars for sale. You can choose according to your needs.

105m³ Organic Fermentation Tank for 100 Thousand Poultry Farm Manure Composting

The organic fertilizer fermentation tank mainly uses microorganisms to biodecompose and decompose the organic matter in the waste, and transform it into organic fertilizer raw materials to realize resource utilization. So we specially designed this equipment for your chicken manure treatment.This equipment can initially process chicken manure and prepare for your follow-up work.

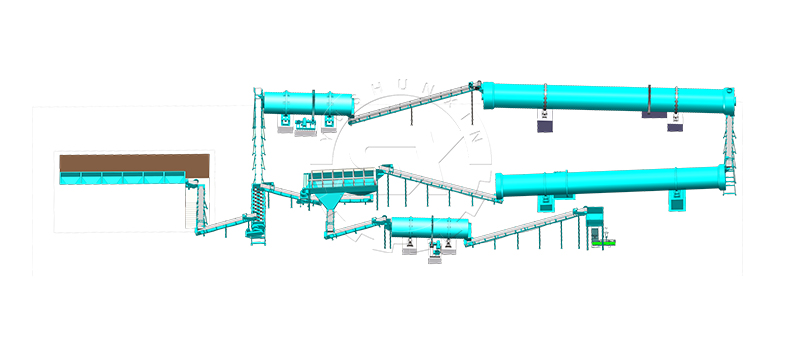

Powder Fertilizer Making Plan for Your Poultry Farm Manure Management

To maximize the use of chicken manure, the best way is to make them into fertilizer. The shape of fertilizer has two types: powder fertilizer and granular fertilizer. Different fertilizers correspond to different equipment and prices. Our equipment manufacturers will give you a detailed introduction.

Budget for Powder Fertilizer Making Plant to Poultry Farm Manure

According to the farm with 100,000 chickens, you can produce 10 tons of chicken manure a day. Then, the capacity for configuring a powder fertilizer production line includes:compost turner, feeding machine, vertical crusher, screening equipment, packaging machine and belt conveyor. So the budget for this fertilizer making plant is 35000 US dollars. This includes the price of the equipment and other costs. If you are interested, inquiry us for details.

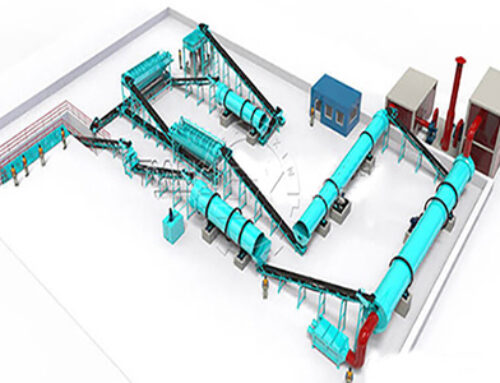

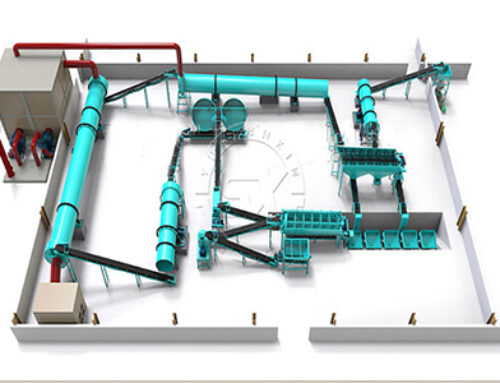

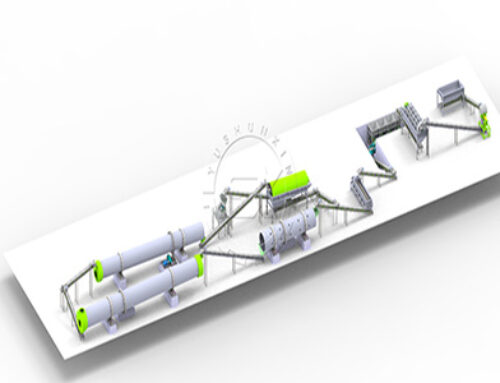

Technology for Making Granular Fertilizer in Your Poultry Farm

The granulation process has two technologies: wet granulation and dry granulation. The equipment used in the two different processes is also different.

Since chicken manure contains a lot of moisture, if you choose dry granulation, you need to dry it first and then granulate it. So the double-roll extrusion granulator and the flat-die granulation machine you can choose. After granulating with these two equipment, you don’t need to dry and cool, and you can pack it directly. Effectively save your budget.

If you choose wet granulation, we have designed drum granulation machine and disc granulator for you. Their yields are all suitable for pelleting at the scale of 100,000 chickens. But you need to dry and cool after granulation. In addition, a large amount of exhaust gas will be generated during the drying process, and a dust collector is also essential.

You can choose the above two granulation processes according to your needs.