Double roller press granulator is the key equipment for fertilizer granulation. And it is suitable for making small scale organic fertilizer pellets and compound fertilizer granules. But if you want to make large scale fertilizer granules, it can also meet your requirements. In addition, it adopts dry granulation method to make fertilizer, which can reduce the cost of drying and cooling. So top 1 dry fertilizer granulation machine is none other than it. Besides double roller granulator, we can also provide you with corresponding machines to setup a complete double roller fertilizer granulation plant.

What kind of pellets can extrusion granulator make?

When you want to use extrusion granulator to make pellets, you need to know what kinds of granules can it produce. In general, there are three types of granules in the following:

Compound NPK Fertilizer Pellets Making

Double roller press granulator is widely used in compound NPK fertilizer production. It can supply nitrogen, phosphorus and potassium to crops in a balanced way. And if you want to make 17:17:17 and 20:10:10 NPK fertilizer pellets, it can also meet your needs. In addition, you can also use ammonium chloride, potassium chloride, ammonium bicarbonate and potassium sulfate, etc as materials to make compound fertilizer pellets in extrusion granulator.

Organic Fertilizer Granules Production

This machine is also suitable for making organic fertilizer granules. When you want to dispose of animal manure and organic waste, you can use double roller granulation machine to produce organic fertilizer granules. Compared with other organic fertilizer granulators, you can turn material into organic fertilizer pellets by using this machine at a lower cost.

Other Chemical Particles Manufacturing

In addition to the above two types, the roller granulator can also produce other chemical granules. Such as snow melting agent and bentonite particles, etc. It can finish the task quickly and easily. So as a multi-functional granulator, double roller press granulator is the best choice for you.

What method does double roller granulator adopts?

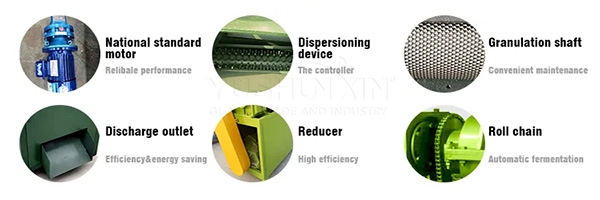

If you want to produce high-quality fertilizer, you must start with the equipment itself.At this time, the double roller granulator produced by our company can meet this requirement.

If you want to use this machine to make granules, you need to further know what granulation method is suitable for it. For this, it adopts dry granulation method, which turn dry powder materials into pellets without adding binder and water. Because this machine accepts the moisture of material below 10%. In addition, it makes use of extrusion force between the two rollers to granulate fertilizer. And after granulation, you don’t need to dry and cool fertilizer granules. It can effectively reduce the cost of drying and cooling.

What is the different from rotary drum granulation machine?

Both double roller press granulator and rotary drum granulation machine are the pelletizers. And they can produce organic fertilizer and compound NPK fertilizer. But there are some differences between them.

Double roller granulator adopts dry granulation method. So after granulation, there is no need to dry and cool fertilizer pellets. But rotary drum granulator is a wet type granulation machine. When you use drum granulation machine to make pellets, drying and cooling is necessary. Because the moisture need to be increased to 45-50% during the drum granulation.

The structure design of the roller granulator and the drum granulator are different. So their working principles are also different. The rotary drum granulator uses the rotating motion of the drum to agglomerate the material particles into balls. While the double roller granulation machine uses mechanical pressure to process powder materials into different shapes of fertilizers.

When you prepare to make fertilizer pellets in a small scale capacity, compaction granulation is the best choice for you. It is suitable for produce 1-3 t/h fertilizer granules. But if you use it to make large scale fertilizer pellets, you only need to increase the number of extrusion granulators. For large scale fertilizer manufacturing, we recommend the rotary drum granulation machine. It can make 1-30 t/h fertilizer pellets.

What is the price of double roller press granulator?

The favourable price is also an important advantage which attracts fertilizer production projects to purchase extrusion granulator. Generally speaking, the price of a double roller press granulator is $3,500-$5,000. Why does it has such an economical price? For one thing, it has a compact design and a capacity of 1-2 t/h. The smaller the capacity, the lower the price. For another, SX is a source factory for fertilizer equipment manufacturing. So there is no extra charge during the transaction.

Technical parameters of SX double roller press granulator

| Model |

Powder(kw) |

Granule Diameter (mm) |

Roller Sheet Size (mm) |

Dimensions (mm) |

|---|---|---|---|---|

| SXDG-1 T |

15 |

3-10 |

150*220 | 1450*800*1450 |

|

SXDG-1.5 T |

18.5 |

3-10 |

150*300 |

1450*800*1500 |

| SXDG-2 T | 22 | 3-10 | 185*220 | 1630*850*1650 |

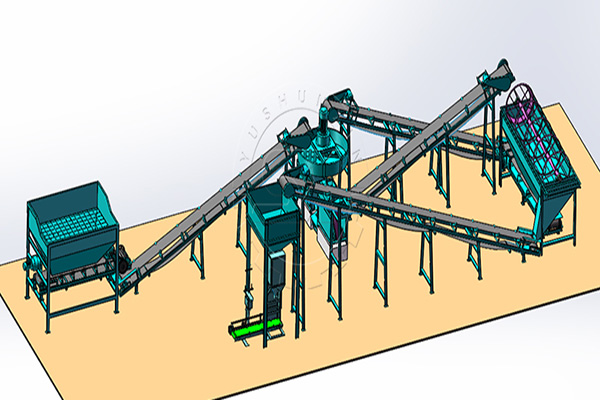

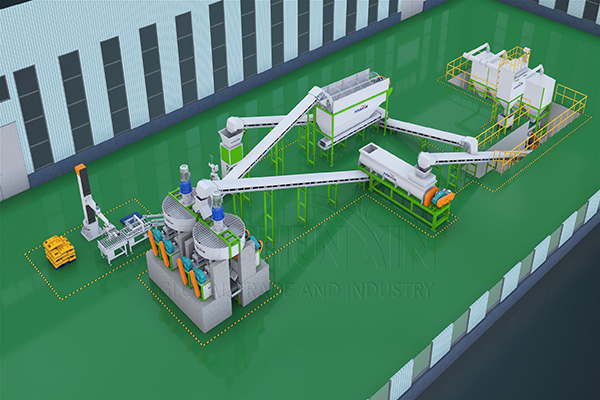

Top 2 double roller extrusion granulation fertilizer line in SX

In order to produce fertilizer pellets continuously with double roller granulation machine, double roller granulation line is a better option. There are 2 hot selling double roller extrusion granulation fertilizer line for your choice. Capacity of 1 t/h and 3 t/h fertilizer making lines. The details are as follows:

How to solve the problems when you use the extrusion granulator?

During the granulation process, there may be problems with the pressure roller gap and the alignment of the ball and socket in the double-roll extrusion granulator. This is when you need to require adjustments.

Satisfactory compaction granulation services

If you buy our company’s double-roll granulator, we will serve you all the way. You don’t have to worry about any problems before and after the purchase.

For quality fertilizer granules making, besides double roller granulator, there also is many granulation equipment that is helpful for you. Such as disc pelletizer, rotary drum granulation machine, flat die pellet mill, etc. Moreover, we can provide you with the customization service of these granulation machines. Welcome to contact us immediately, we will try our best to offer you the best solutions for your own fertilizer manufacturing smoothly and successfully.