How to Dispose of Bio NPK Materials in Brazil?

The customer from Brazil wanted to know how to dispose of bio NPK materials. Because improper handling of these materials will lead to the generation of harmful gases and impurities, pollute the production environment and affect the quality of the final fertilizer. For this, we introduced the bio NPK materials disposal process to him in detail.

Crushing Material with Bio NPK

Next, the most important step, crushing materials into fine powder bio NPK fertilizer. The finer the powder, the better the quality. But they have high moisture, so choosing semi-wet material shredder is an excellent option.

Bio NPK Materials to Screening

In addition, screening also plays an important role in bio NPK fertilizer production. Rotary screener can remove waste, like stones, cigarette butt, etc from powder bio NPK fertilizer. So the purity of final fertilizer is improved.

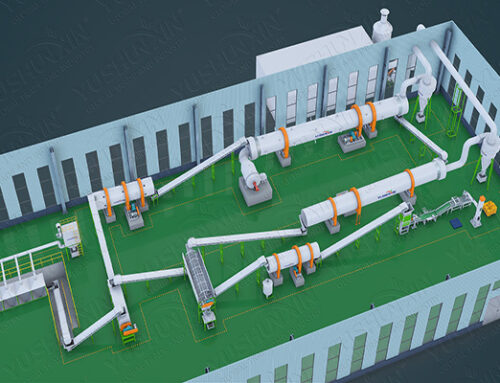

What Equipment is Used in Bio NPK Granules Plant in Brazil?

Then after disposing of materials, we continue to introduce the equipment used in the production of granular bio NPK fertilizer to Brazilian customer.

Bio NPK Fertilizer Granulator

Because the customer from Brazil is not sure about his output, so we recommended him two granulators suitable for small output and large output for him to choose. Pan pelletizer or rotary drum granulator. The former has a granulation rate of 93% and can process 1-8 mm with a higher hardness and small scale. However, you need a more large capacity bio NPK fertilizer pelletizer, you can choose the latter. They both adopt wet granulation method, you can choose them according to your requirements.

bio npk fertilizer dryer

If you use the above granulation equipment to make bio NPK fertilizer, dryer and cooler is necessary. They can reduce the moisture content of bio NPK fertilizer pellets to below 10%. This means lower possibility of pulverization, So the produced bio NPK fertilizer is more convenient for transportation and storage.

coating equipment for bio npk fertilizer

In granular bio NPK fertilizer manufacturing process, coating machine is essential. For one thing, it can be used to add a protective film to the pellets. This makes bio NPK fertilizer have a longer storage time and effect. For another, you can use it to add biology.

packaging bio npk granules

Finally, packing finished bio NPK fertilizer. In SX, for different capacity of fertilizer, single or double bucket automatic bagging machine is the best choice. Both for organic fertilizer production and NPK fertilizer making.

Which bio NPK fertilizer plant is more suitable for you?

Do you know which bio NPK fertilizer manufacturing system is more suitable for you? This Brazilian customer also wanted to know about this.

Material shape

When you use powder or powder + granular chemical and organic materials, we recommend you choose bio NPK fertilizer granulation line. However, when it comes to granular bio complex fertilizer materials processing, it is advisable to setup a bio NPK fertilizer blending plant.

Budget

For those who have enough budget for bio NPK fertilizer manufacturing, our bio NPK fertilizer granulation system is your optimal option. Adversely, if you need a bio NPK fertilizer plant design for low cost production, you can choose bio NPK fertilizer mixing line.

Capacity

These two bio NPK fertilizer production plans both can be used not only in small scale biio NPK fertilizer making, but also in large scale bio NPK fertilizer production. But there are also some differences between them. The largest capacity of bio NPK fertilizer granulation line is 30 t/h. But the large scale bio NPK fertilizer blending system can process 20-40 tons of bio NPK fertilizer per hour for you.

Area occupation

If you have a big workshop for bio NPK fertilizer preparation, bio NPK fertilizer granulation line is your best choice. In addition, for starting bio NPK fertilizer making in a small place, we also can offer you NPK fertilizer blending system.

What is the cost of bio NPK fertilizer plant?

During bio NPK fertilizer production plant setup, cost is an item customer from Brazil must focus on. According to your budget for bio NPK fertilizer making, SX can offer you suitable fertilizer production project and equipment. Generally, the cost of bio NPK fertilizer manufacturing consists of equipment purchasing, area preparation, labor force and energy consumption.

What are the Benefits that SX Bio NPK Fertilizer Equipment Can Provide You?

Finally, we introduced the benefits to the crops of the bio NPK fertilizer produced by SX fertilizer equipment to our Brazilian customer.

Improve product quality and reduce harmful accumulation. Due to the dual effects of the live bacteria in the bio NPK fertilizer and the fertilizer-preserving synergist, it can promote the conversion of nitrate in crops and reduce the accumulation of nitrate in agricultural products. Compared with the application of chemical fertilizer, it can reduce the nitrate content in the product by 20- -30%, increase the VC content by 30- -40%, and increase the soluble sugar by 1-4 degrees. The product tastes good, keeps fresh for a long time, and is resistant to storage.