Bulk blending fertilizer production line can blend kinds of fertilizer granules to the specified fertilizer in a proportion. The process technology is widely used and it has bright market prospect. Below I will introduce to you the relevant content of the bb fertilizer production line, including the production process of bb fertilizer. And its related raw materials and advantages, etc. Meanwhile, we provide you different configurations for your fertilizer making requirements.

How to manufacture bulk blending fertilizer?

How to make BB fertilizer? It is necessary to buy professional equipment for fertilizer blending plant. Because it is the secret of finishing bulk blending fertilizer smoothly and quickly. But what machine is needed for BB fertilizer production? In general, you need the following four fertilizer processing machines.

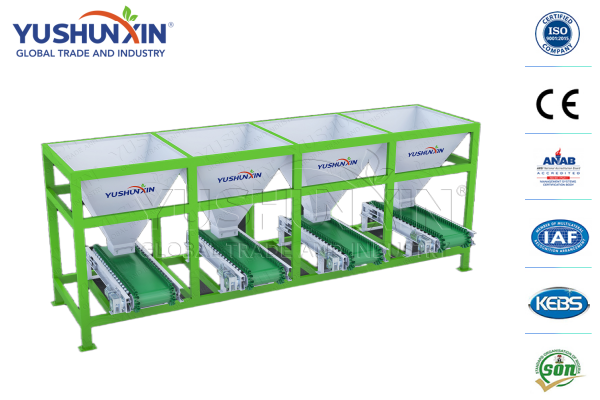

Batching machine

BB fertilizer is a mixture of a variety of chemical materials with a certain proportion. If the proportion is changed, the final fertilizer will no longer be suitable for local farming conditions and even cause damage to it. But how to ensure that you can make BB fertilizer strictly according to the formula proportion? Using batching machine, which adopts an electrical weighting system and feeds different chemical materials in order instead of all at once. Therefore, it can feed required materials with high precision.

BB fertilizer mixer

Bulk blending fertilizer making, as the name suggests, mixing machine plays an important role in this process. For this, we especially design professional BB fertilizer mixer. It overcomes the mixtures chromatography and distributaries phenomena caused by different proportions of raw materials and particle size. Moreover, it also solves the influence of material properties, mechanical vibration, air pressure, etc. So it can help you blend various chemical materials evenly to ensure the nutrient balance of your BB fertilizer.

Automatic packaging machine

After mixing, you can package the compound fertilizer directly. What a simple process! Then to finish blending fertilizer faster, we recommend you buy an automatic bagging machine. It has an electrically automatic weighting system, which has a quantitative precision of 2%o. Therefore, it can help you pack final BB fertilizer into 10 kg, 25 kg, 50 kg, etc in a short time. In this way, you can transport, store and sell them more conveniently.

Conveyor

If you want to keep bulk blending fertilizer manufacturing smoothly, it also needs to buy conveyor. It is used to transport chemical materials from one equipment to another. For this, we can provide you belt conveyor, mobile belt conveyor, bucket elevator,etc.

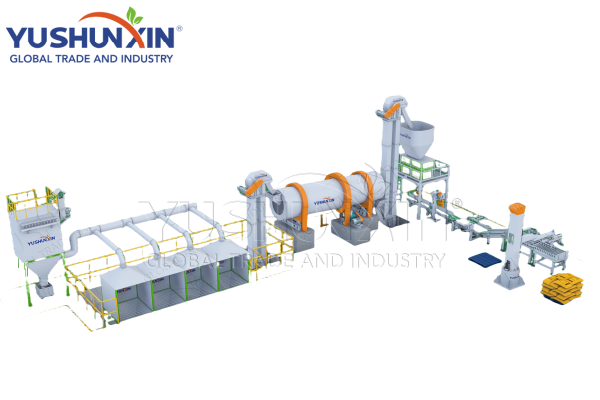

2 Hot selling BB fertilizer production lines for your choice

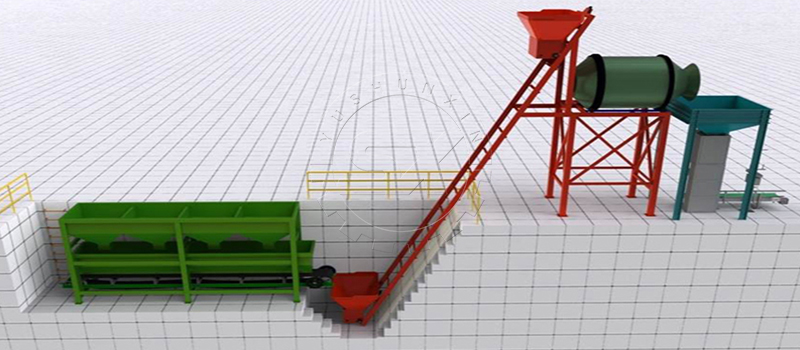

In order to different requirements of fertilizer suppliers, we especially design fertilizer blending production projects with different capacities. One is designed for small scale compound fertilizer making plants, which need to produce 5-10 tons of BB fertilizer per hour. Another one is rotary drum mixing fertilizer line, which is suitable for preparing bulk blending fertilizer in a large scale.

5-10 t/h BB fertilizer making plan design

When you need a BB fertilizer making line with a capacity of 5-10 t/h, we recommend you choose our small scale fertilizer blending system. It consists of static batching machine, large angle belt lifter, BB fertilizer mixer, single bucket quantitative packing scale. It adopts the operation method of feeding in positive rotation and discharging in reverse rotation. Easy operation. In addition, because of the special internal spiral mechanism and unique three. dimensional structure, it can mix materials evenly and export fertilizer without blocking.

30-40 t/h drum type BB fertilizer making line

Provided you want to set up a large scale fertilizer blending plant, you can choose our drum type fertilizer mixing line. It replaces the BB fertilizer mixer with drum type BB fertilizer blender, which has a larger output of 30-40 t/h. That is, it can help you produce 180,000-250,000 tons of bulk blending fertilizer a year, Correspondingly, it is advisable to upgrade single bucket packing machine to double buckets automatic bagging scale. In this way, you can finish large scale mixing fertilizer manufacturing quickly.

Why does BB fertilizer production line that wins customer ?

Our company’s BB fertilizer production equipment has many advantages, let me introduce it to you.

The key to BB fertilizer production lies in its raw material proportion and type. If you want to produce high-quality and highly nutritious BB fertilizer, our equipment can meet your requirements. There are many types of ingredients, suitable for 3~12 kinds of materials, increasing your choice for your production plant.

If you want to overcome the shunting phenomenon caused by the different specific gravity and particle size of raw materials, this equipment from our company can solve this problem very well. The mixing is uniform, the speed is fast, and the service life is long. It can also solve the impact on the system due to material characteristics, mechanical vibration, air pressure and other factors.

Considering your site problem, we can individually design your site. And the land occupation will be reasonable and compact. Ensure that not wasting the space to the greatest extent.

8 Highlights to possess BB fertilizer plant

Raw materials for making BB fertilizer in your plant

The technical key of producing BB fertilizer lies in its raw material and specific gravity distribution. Different raw materials produce different BB fertilizers, and different specific gravity will also lead to different structures of fertilizers, which will affect the state of fertilizers.Here are a few examples for your reference.