What is the detailed technical specification of rotary drum granulator?

When you buy this rotary drum granulation machine, it is important for you to know about the technical parameters. And there are many types of rotary drum granulators in YUSHUNXIN. So the followings are the specific technical specifications.

Technical parameter of rotary drum pelletizer

| Model | Power (kw) | Diameter (mm) | Length (mm) | Installation Angle | Rotary Speed (r/min) |

Capacity (t/h) |

|---|---|---|---|---|---|---|

|

SXZGZ-1240 |

5.5 | 1200 | 4000 | 2-5° | 17 |

1-3 |

|

SXZGZ-1560 |

11 | 1500 | 6000 | 2-5° | 17.5 |

3-5 |

|

SXZGZ-1870 |

15 | 1800 | 7000 | 2-5° | 11.5 |

5-8 |

|

SXZGZ-2080 |

18.5 | 2000 | 8000 | 2-5° | 11 |

8-15 |

|

SXZGZ-3210 |

37 | 3200 | 10000 | 2-5° | 9.5 |

15-30 |

3 Designs of drum pelletizer help you make high quality fertilizer pellets

In the process of large scale fertilizer granulation, there is an item most fertilizer manufacturers focus on. Because of wet granulation, the materials are easy to stick to the wall. This will affect the granulation efficiency of rotary drum fertilizer pellet production and cause serious erosion to the granulator. For this, we especially upgrade the designs as follows:

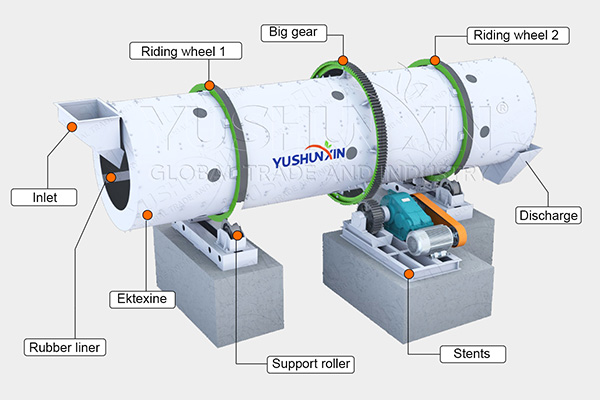

Rubber lining

To make granulation equipment withstand the erosion of large scale fertilizer processing, one best way is improving the corrosion resistance. On the basis of using Q235B boiler steel to produce the rotary drum pelletizer, we equip it with a rubber lining. Therefore, this granulation equipment has better erosion resistance and a longer service life.

Stainless press stripes

In order to improve the corrosion resistance of rotary drum pellet making equipment, we adopts stainless steel press strips on rubber lining equipment. They can firmly fix the lining to the inner wall of drum pellet making machine and have high erosion resistance because of using stainless steel as materials.

Cleaning holes

But after a long time running, there are still some materials sticking to the inner wall. And the granulation efficiency will be affected. Then how to treat those sticking materials? You can clean them up with special holes. Using hammers to knock those cleaning holes. The materials will fall under the action of vibration.