Manure Separator for Organic Material Moisture Reduction

In general, organic fertilizer is made of cow dung, chicken manure, sludge, biogas waste, etc. They usually are a mixture of liquid and solids and have a high moisture content. When the water content of the raw material is higher than 70%, the fermentation rate of organic fertilizer will be significantly reduced.

FAQ

Manure Drying Machine for Organic Fertilizer Granules Production

As mentioned above, moisture content control throughout the whole organic fertilizer preparation line. And the international requirement of organic fertilizer moisture content is less than 14%. But in general, after granulating, the water content of your organic fertilizer is 20%-30%. Therefore, you need an equipment for excessive moisture removal.

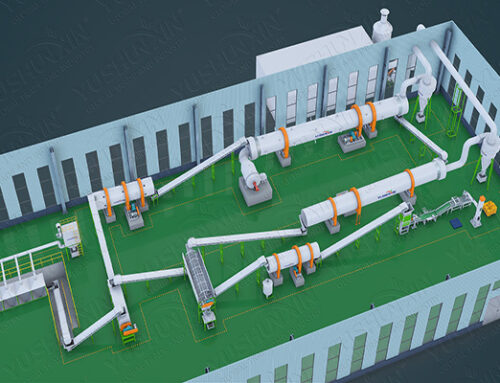

manure drying machine for organic fertilizer production

In this case, SX can offer you rotary dryer, which makes use of a high temperature environment to reduce the water content of your organic fertilizer granules. But how to generate the high temperature required by drying? Hot blast furnace is designed for this. Then after drying, the temperature of fertilizer particles will increase and the moisture contained by fertilizer pellets will be transpired to the surface. This makes it inconvenient for further processing. Therefore, it needs cooling equipment, which can reduce the temperature and remove the moisture on the fertilizer surface.

What’s more, if you are worried about producing more dust, SX can also solve this problem. We have specialized dust collector for this. Cyclone dust collector and bag filter dust collector. Hence, they can better maintain production environment.

Automatic Bagging Machine for Sale

The equipment for packaging is also on of the top 3 auxiliary machines used in organic fertilizer making in 2023. Packaging is the final step of organic fertilizer production. After bagging, the fertilizer is easy to transport, store and use. But manual packaging will take a lot of time, using professional machine can greatly shorten this time.

In SX, there are various packing machines for your choice. They can meet the different requirements of fertilizer manufacturers. If you need a equipment for large scale organic fertilizer making, you can choose double bucket automatic packaging scale or ton bag packing equipment. But for small scale organic fertilizer plant, single bucket bagging machine is enough. In addition, we especially design different bagging machines for powder and granular fertilizer production. You can choose according to your needs.