Because 20-10-10 NPK fertilizer can supply nutrients for crops in a targeted way, most fertilizer production project to invest in NPK compound fertilizer production. Like the customer from Indonesia, who inquired about 20-10-10 NPK fertilizer making machines on 12th August 2023. Finally, after discussing the details, he chose our NPK rotary drum granulation line. The following are the specific details of our communication in this case:

What Granulator is Suitable for Large Capacity 20 10 10 NPK Fertilizer Making?

The client from Indonesia wanted to use Nitrogen (urea), Rock Phosphate, DAP/MAP (depend on Composition), KCL or ZK, clay to prepare large capacity of 20-10-10 NPK fertilizer pellets. So first of all, it is essential to buy a type of suitable chemical pellet making equipment.

How to Setup a NPK Rotary Drum Granulation Plant in Indonesia?

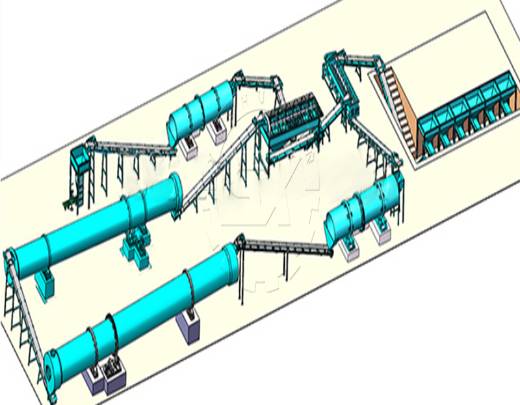

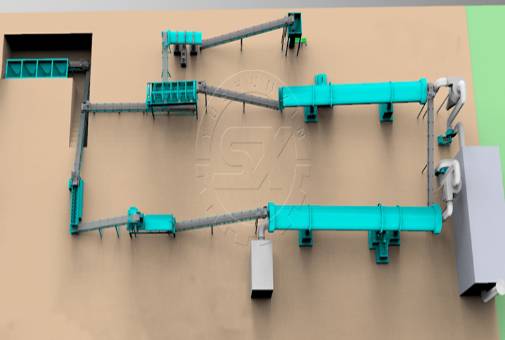

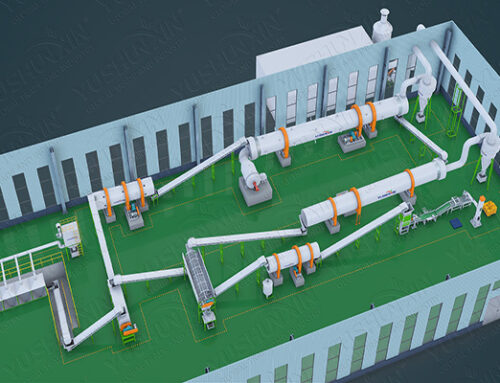

Then Indonesian customer asked us how to setup a NPK rotary drum granulation plant? We told him buying drum pelletizer only is not enough. It is necessary to choose other fertilizer processing machines to establish a professional fertilizer granulation line. In this process, cost and factory area are two items you must pay attention to. So to establish a rotary drum fertilizer granulation factory, you need to do the following things:

What Equipment is Needed in a Rotary Fertilizer Granulation Line?

When you plan to create a 20-10-10 NPK fertilizer granulation line, besides rotary drum granulator, you also need to buy batching machine, crusher, mixer, screener, dryer, cooler, dust collector, dust fall room, coating equipment and belt conveyor. These machines can upgrade your the quality of NPK fertilizer.

Cost also plays an important role in 20-10-10 NPK rotary drum granulation plant setup. It contains the costs of material preparation, equipment, workshop building, energy consumption, worker employment, etc. Then because our rotary drum granulation system has characteristics of low energy consumption and high automation. And as a source factory of fertilizer equipment, SX can provide you with equipment at a favourable price. You can setup the rotary drum granulation plant at a low cost.

What is the Area Occupation of a NPK Rotary Fertilizer Pellet Making System?

The area occupation also will vary according to the capacity and configuration. Generally, a 10 t/h 20-10-10 NPK rotary drum granulation line needs an area of 1400-1500 m2. And you need to prepare a 3145-5760 m2 site for a 20 t/h NPK drum pellet making system installation.

What Factor Affect the efficiency of Granulation in NPK Drum Pelleting Line?

Finally, customer from Indonesia wanted to know what factors will affect the granulation efficiency, and what should be paid attention to at ordinary times.

These two are the primary factors that determine the granulating rate and particle roundness. Because the NPK material depends on the surface tension, the right amount of liquid, the extrusion force generated by the rolling materials to granulate. During the process, it takes small particles as the core and rolling to absorb other materials, finally bonding into balls. So within a certain period of time, the higher the rolling frequency, the higher the granulation rate, and the more rounded granule.

Too much material sticking to the wall will increase the friction between the material and the cylinder wall. Then the material in the machine will be lifted too high and thrown down from the top, so the particles are not round and too large. There are two reasons for this situation: First, there are too many viscous materials. We can solve this situation by changing the process formula and reducing the amount of viscous materials. In addition, if the granulator has non-smooth interior, the materials also have the possibility of sticking. In this case, we can increase the smoothness of the granulator by changing the internal NPK material.