Agriculture is the largest sector of the economy in Yemen. So fertilizers are in high demand in Yemen. And because of balanced nutrient content and good soil improvement effect of organic fertilizer, using it in organic farming has been a new development direction for agriculture in Yemen. Therefore, many companies plan to invest in organic fertilizer factory. On 3rd August 2023, a customer from Yemen inquired about how to set up an organic fertilizer plant. Then after negotiation on details, we design a customized project for organic fertilizer production according to customer’s actual conditions. The following are the specific details of the communication in this case:

What is the Design of an Organic Fertilizer Plant in Yemen?

When you want to set up an organic fertilizer production project, factory areas are also two aspects you must consider. Usually, the whole organic fertilizer making area is divided into three parts:

As the name suggests, this is an area for poultry manure composting. And generally, it will vary with capacity. The larger the capacity, the larger the composting area. For example, the customers from Yemen wanted to use crawler type compost machine to prepare poultry waste compost. You need to prepare an area of 600㎡-3000㎡ according to the capacity of 1-20 tons per hour. Can we make compost with a smaller space? Of course. You can choose our fermentation tank, which only needs 10-30㎡.

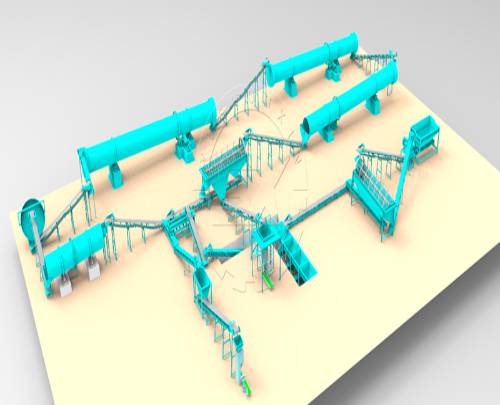

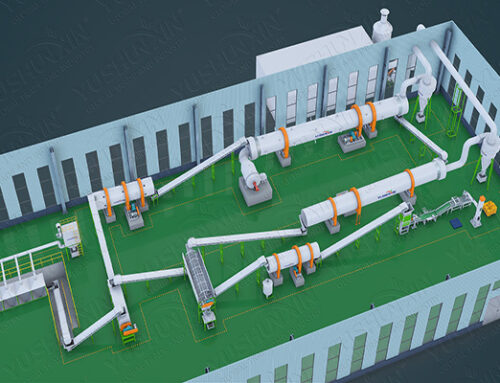

This area is designed for installation of equipment from feeder to packaging. For 1-20 tons per hour organic fertilizer pellets manufacturing, it needs about 1000-5000㎡. And for organic powder fertilizer production, it needs about 400-2500㎡.

Besides the above two areas, you also need to prepare a place for finished poultry manure fertilizer storage. However, this only needs a small area.

What Differences Between Disc Pelletizer and Drum Granulator?

This Yemenis client wanted to make organic fertilizer into granules. For this, pan pelleting machine and rotary drum granulator are both an ideal choice for organic fertilizer granulation. But they are different in several aspects. First, they are different in capacity. The former, whose capacity is 1-6t/h, is more suitable for small scale organic ferilizer production. Meanwhile, the latter has a capacity of 1-30t/h and is an optimal option for making organic fertilizer in a large scale. In addition, they also have a difference in price. If you have enough budget, rotary drum granulating machine is the best choice. If not, disc pelletizer is designed for you.