There are three types of fertilizer equipment that are more popular in the fertilizer production project: double-roller granulator, fertilizer bagging equipment and manure separator. Their role in the fertilizer production line is very important, which includes three process of dehydration, granulation and packaging. Below our fertilizer machine engineers will introduce them in detail.

Using Manure Separator Before Composting in Your Organic Fertilizer Production Line

Meet Bagging Requirements for Solid-liquid Separator to Make Fertilizer

Produce Powder Fertilizer to Bagging Machines in Your Fertilizer Project

After composting, loader type feeding, crushing and mixing, you can make powder fertilizer. After production, in order to facilitate transportation and sales, you need to pack it. The capacity of this bagging machine is 25-50kgs/bag, and you can configure it reasonably according to your output. If you want to improve packaging efficiency, you can buy a double-bucket automatic packaging machine. It has two packaging ports, and the quantitative accuracy of the system is two thousandths. This packaging machine is an essential equipment in your production line.

Double-roller Extrusion Granulator to Make Dry Fertilizer in You Fertilizer Production Project

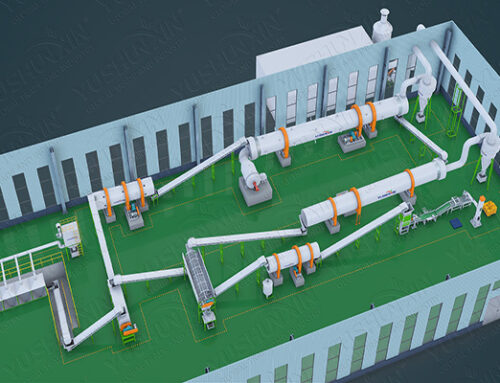

Roller granulation belongs to dry granulation, and the production process is relatively simple. After the preliminary composting, crushing and stirring, you can use the double-roller granulator to granulate. No subsequent drying and cooling is required. So using this equipment to granulate can reduce your budget and improve production efficiency.

Benefits to Use Double-roller Press Granulator for Process of Producing Granular Fertilizer

Adjustable Granular Size

Because the double-roll extrusion granulator relies on roller skin extrusion to granulate in the process of producing granular fertilizer. So, if you want to change the size of the granular fertilizer, you must start with the roller skin. You can customize the size of the roller skin according to your needs, so that you can produce the particle size you need.