Cow dung as a raw material is essential in the fertilizer production line. It is high in nutrients and has a good nourishing effect on the soil. Moreover, its output is large, and its cost is also within a controllable range. Therefore, the cow dung production line is very popular with fertilizer manufacturers. Our company has a full set of production line equipment for you to choose from. For details, please see the introduction below.

How to make cow dung into fertilizer?

You can see cow dung everywhere on the farm, but those farm people sometimes don’t know how to deal with the cow dung better, so that they can play beyond their original value. At this time, some people will make them into fertilizer. But how do you turn cow dung into fertilizer?

This is the complete process of making cow dung into fertilizer.

Types of cow dung production line for your requirement

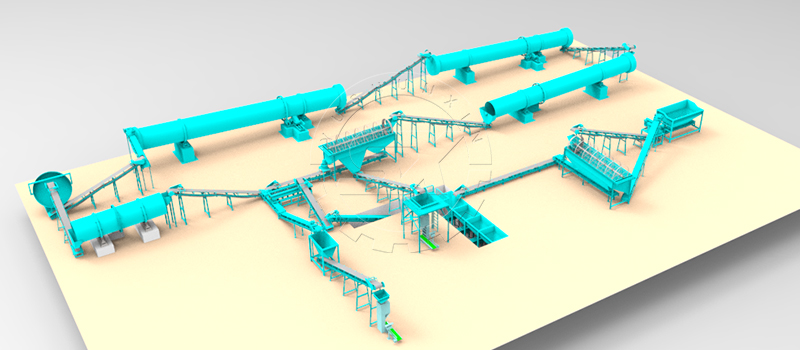

Cow manure production line is divided into two types: powder fertilizer production line and granular fertilizer production line.

Powdered Fertilizer Making Plant

Dehydrating the excess water in cow manure. Then carry out aerobic fermentation to quickly decompose, so that the fertilizer can hold the water but not drip. You can use our company’s organic fertilizer fermentation tank, which has professional electronic control equipment to ensure a more accurate fermentation effect. You must crush and screen all materials to select materials suitable for subsequent fertilizer making. Because it is in powder form, you can directly package and bin after sieving.

Granular Fertilizer Production Line

The previous steps are the same as the powder production line, but there is a difference in the granulation step. Because there are two granulation processes: dry granulation and wet granulation. For dry granulation, it is recommended that you can buy our company’s double-roll granulator, which is suitable for this process. And you can directly package later to reduce costs. For wet granulation, if your output is large, it is recommended that you buy a drum granulator. If the output is small, buy a disc granulator. Because of wet granulation, you need to dry and cool later. Finally it’s ready to pack.

You can choose the production line that suits you according to your needs.

How to improve drying efficiency in your cow dung production line?

In the cow dung production line, the efficiency of the dryer is closely related to the economic benefits of the customer. Improving its efficiency is the key issue to improve the economic benefits of customers.

Cow dung fertilizer production price

Due to the different output of cow dung production line, the price is also different. Below I will help you make a simple plan according to different output, and provide you with some suggestions.

Powdered Cow Dung Production Line

Output:1-3 tons per hour Budget:35,000 US dollars Site:800 square meters

Output:5 tons per hour Budget:45,000 US dollars Site:1500 square meters

Output:10 tons per hour Budget:60,000 US dollars Site:3000 square meters

Output:20 tons per hour Budget:90,000 US dollars Site:5000 square meters

According to the fertilizer status of this production line, the required equipment includes:compost turning machine, feeding machine, vertical pulverizer, screening machine, packaging machine, belt conveyor. From the above, the budgets and site sizes for different productions are also different.

Granular Cow Dung Production Plant

Output:1-2 tons per hour Budget:110,000 US dollars Site:2,000 square meters

Output:3 tons per hour Budget:140,000 US dollars Site:3,000 square meters

Output:5tons per hour Budget:190,000 US dollars Site:24500 square meters

Output:10 tons per hour Budget:360,000 US dollars Site:5500 square meters

Output:20 tons per hour Budget:550,000 US dollars Site:10,000 square meters

According to the fertilizer status of this production line, the equipment required for 1-5 tons includes: compost turning machine, feeding machine, vertical crusher, two of screening machine, batching machine, stirring tooth granulator, drying and cooling machine , coating machine, packaging machine, belt conveyor. Due to the large output of 10-20 tons, the granulator becomes a drum granulator and a disc granulation machine.